Enhancing Your College Journey: Applying Design for Manufacturing (DFM) & Design Failure Mode and Effect Analysis (DFMEA) in Your Club

- Bruna Osako

- Mar 27, 2024

- 4 min read

Updated: Apr 2, 2024

Today, I'm EXCITED to delve into how integrating Design for Manufacturing (DFM) and Design Failure Mode and Effect Analysis (DFMEA) into your club activities can elevate your college experience. These skills are in high demand by companies, making them valuable assets for securing future opportunities. For those unfamiliar, Design for Manufacturing optimizes product designs for efficient production, while Design Failure Mode and Effect Analysis identifies and mitigates potential design failures. Let's explore how these concepts can enrich your club involvement. Here are the key points I'll focus on:

Design for Manufacturability (DFM) Cycle and Application Guidelines

Design for Manufacturability and Assembly (DFMA) Cycle and Application Guidelines

Design for Manufacturability (DFM) Cycle and Application Guidelines

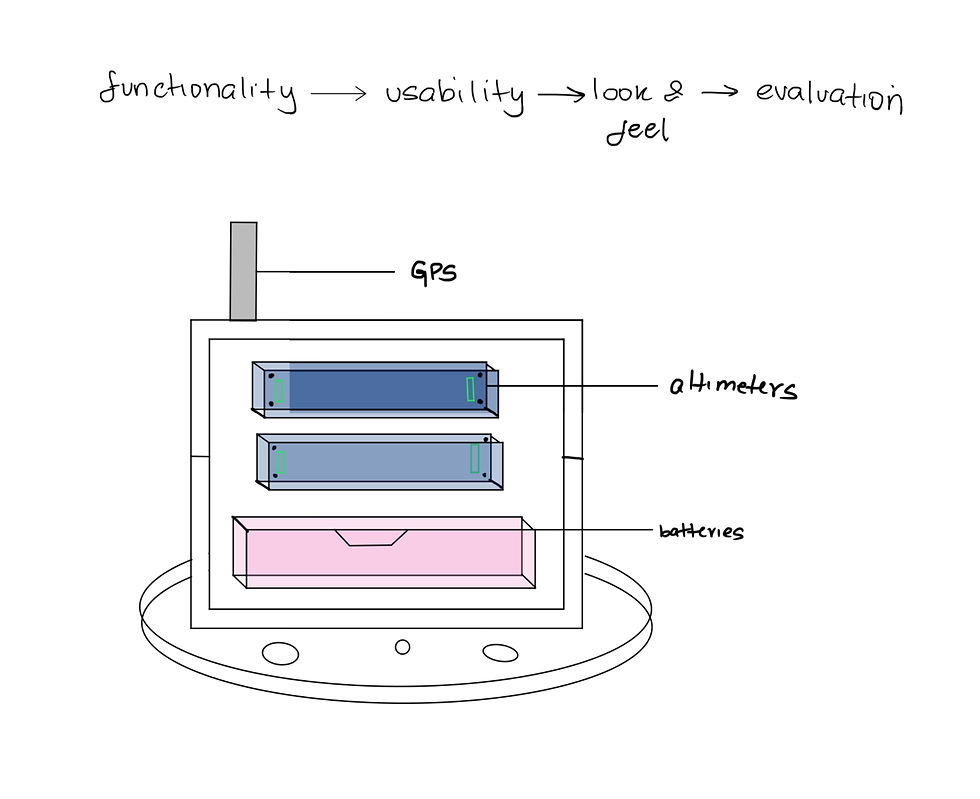

In my first year with the team, I was assigned to the recovery sub-team, where my primary responsibility was the design of the Avionics Bay. This critical component serves as the hub for various electronics, housing essential equipment such as altimeters, telegps units, batteries, and safety switches. Integrating the Design for Manufacturability (DFM) cycle into our club's workflow proved instrumental in managing time effectively and refining the design process.

Today, I aim to broaden our perspective by focusing on team management. Delegating tasks and overseeing multiple projects can often feel overwhelming, but by integrating a standardized cycle and establishing a feasible timeline, this process becomes considerably more manageable. These steps not only equip you with the skills to address challenges throughout the year but also provide a structured approach to problem-solving. We'll delve deeper into these strategies shortly, discussing practical approaches to tackle various scenarios effectively.

Initial Design Assessment: Evaluate the initial design to identify potential manufacturing challenges and opportunities for improvement.

Collaboration: Foster collaboration between design, engineering, and manufacturing teams to ensure that design decisions align with manufacturing capabilities. Pose inquiries, engage in discussions with faculty, senior members, and seek constructive feedback.

Simplification and Standardization: Simplify complex designs and standardize components where possible to reduce production complexity and costs.

As an example: last year we had complications with the booster and dart rocket configuration, so this year we are planning to lower complexity and focus on the systems.

Material Selection: Choose materials that are readily available and suitable for manufacturing processes, considering factors such as cost, availability, and performance.

Prototyping and Testing: Create prototypes to validate the design and manufacturing processes, allowing for adjustments and improvements as needed.

Continuous Improvement: Implement feedback loops to incorporate lessons learned from previous manufacturing cycles, driving continuous improvement in design and manufacturing processes.

ALWAYS BE OPEN TO CHANGES AND IMPROVEMENT!!!

2. Design for Manufacturability and Assembly (DFMA) Cycle and Application Guidelines

When discussing the significance of continuous improvement, it's crucial to not only emphasize the pursuit of new enhancements but also to meticulously identify potential failures. By delving into Failure Modes and Effects Analysis (FMEA) and implementing its principles, we can comprehensively evaluate the landscape of possible shortcomings. This proactive approach ensures that our improvement efforts are not only forward-thinking but also rooted in a thorough understanding of existing vulnerabilities and areas ripe for enhancement.

Dentify Components and Functions: Begin by identifying all components and their respective functions within the system or product under consideration.

Consider the following questions:

"Why is a Payload necessary?"

"Do we require Parachutes?"

What about Avionics?

And Airbrakes?

What's the purpose of the Motor?

Brainstorm Failure Modes: Anticipate all potential failure modes for each component. This includes considering how each component could fail to perform its intended function.

Assess Severity: Evaluate the severity of each potential failure mode. Consider the impact it would have on the overall system, including safety, performance, and customer satisfaction.

Determine Causes: Determine the root causes of each identified failure mode. This involves analyzing factors such as design flaws, material properties, environmental conditions, and human error.

Evaluate Occurrence: Assess the likelihood of each failure mode occurring. Consider factors such as component variability, manufacturing processes, and environmental stressors.

Rate Detection: Evaluate the effectiveness of current detection methods in identifying each failure mode before it reaches the customer. This includes testing, inspections, and quality control measures.

Calculate Risk Priority Number (RPN): Multiply severity, occurrence, and detection ratings to calculate the Risk Priority Number (RPN) for each failure mode. This helps prioritize which failure modes to address first.

Define your risks clearly and prioritize efforts to mitigate them effectively.

That's why conducting a risk analysis is essential, along with utilizing a matrix to visualize your risks and take accountability for them.

Prioritize Actions: Focus on addressing high-risk failure modes with the highest RPN values. Develop and implement actions to mitigate or eliminate these risks.

Implement Design Changes: Modify the design to eliminate or reduce the likelihood of failure modes with high RPN values. This may involve redesigning components, selecting alternative materials, or improving manufacturing processes.

Document and Review: Document all findings, actions taken, and results of DFMEA analysis. Regularly review and update the DFMEA throughout the design process and product lifecycle to ensure continuous improvement.

DOCUMENT IT!!!!!

This is the overleaf website we use to do our technical report

By following these steps, you can effectively apply DFMEA to identify and mitigate potential failure modes in the design phase, ultimately improving the reliability and performance of your product or system.

Comments